Maytech.cn

In Stock 2pcs/ 5pcs MTSPF7.5HK 5V based on V75/300 SuperESC Watercooled Speed Controller

In Stock 2pcs/ 5pcs MTSPF7.5HK 5V based on V75/300 SuperESC Watercooled Speed Controller

Couldn't load pickup availability

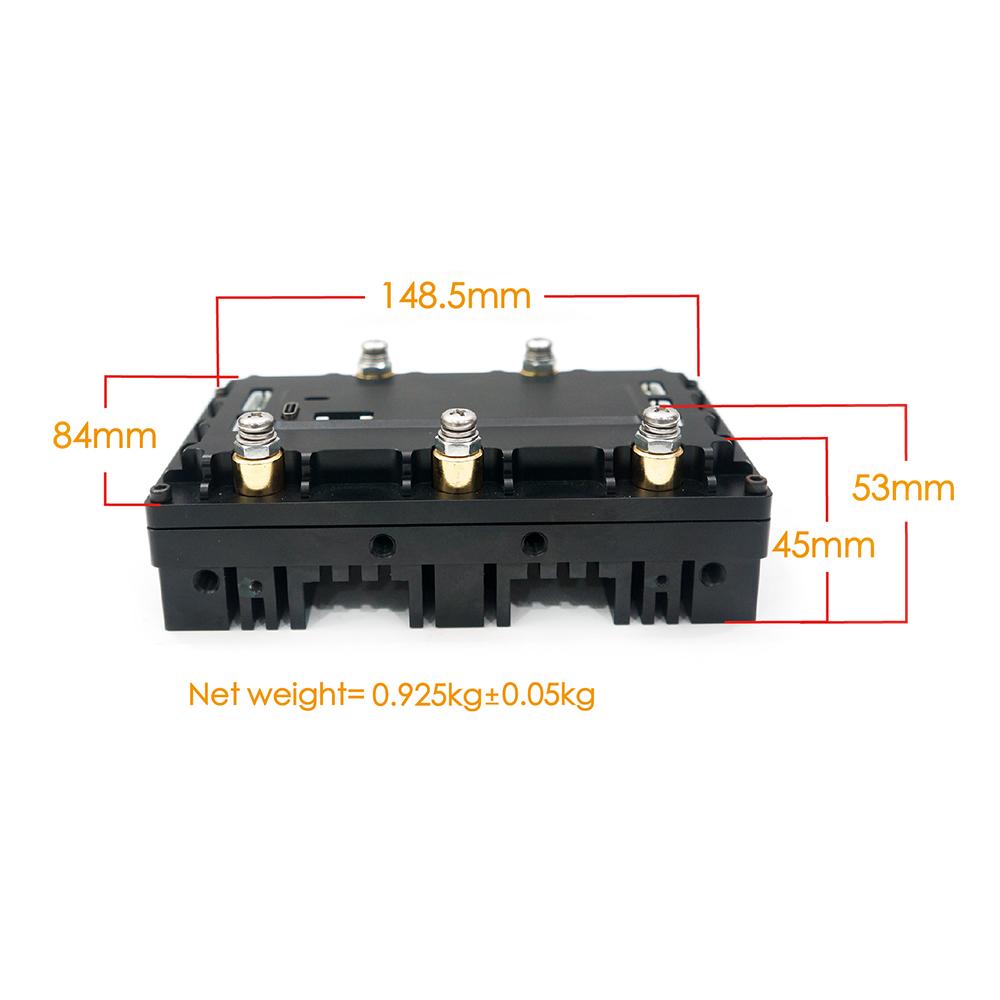

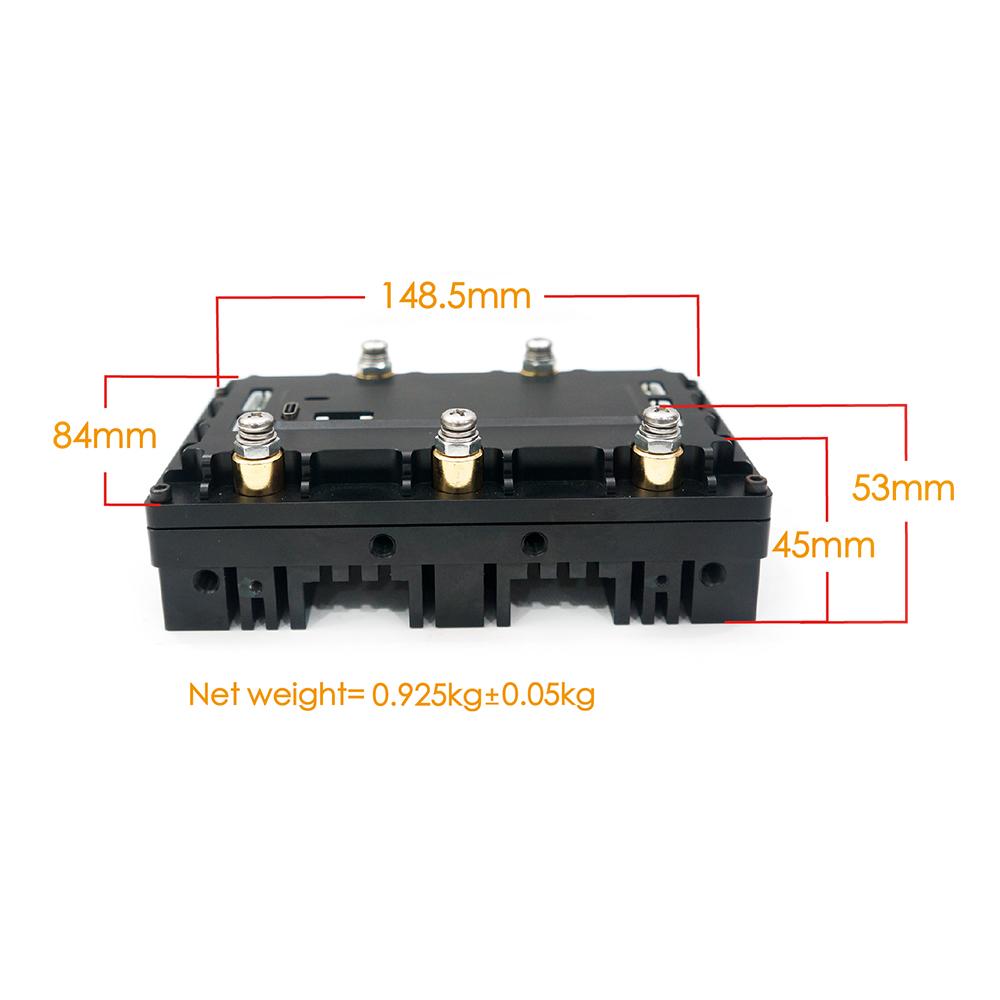

| Model No. | MTSPF7.5HK |

| Input Voltage | 5-18S Lipo (18V-75V) |

| Hardware | based on V75/300 |

| Firmware | Updatable |

| Current | 300A |

| Software | VESCTOOL Compatible |

| Heat Sink | With |

| Water Cooling | With |

| Capacitors | 9pcs 100V 470μf capacitor |

| Application | electric skateboard, fighting robot, e-bike, electric motorcycle, efoil, electric surfboard, watercraft, electric boat, underwater ROV, agricultural robots, robotic sprayer, etc |

-Absolute Maximum Current: 150A (According to your motor current)

-Battery Current Max: ≤150A (According to your battery discharge current)

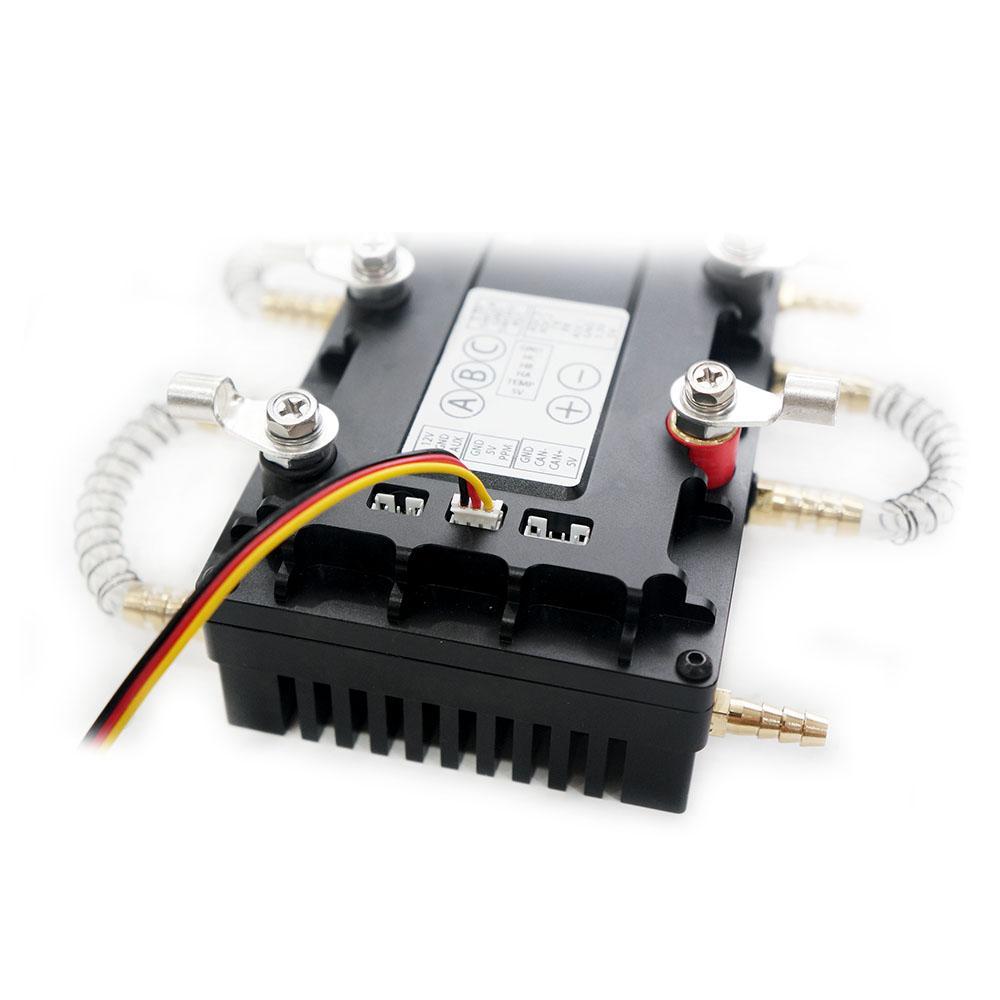

Ports definitions:

- AUX port to supply 12V and 5V to external device;

- PPM port to connect PPM transceivers; Never connect one receiver to two or more VESCs in an array ! Permanent damage may result from Y-PPM wiring

- CAN Port for CAN communication with other devices and controller arrays; Only connect CAN L and CAN H ! GND pins and 5V should never be connected in aVESC array.

- Sensor port for motor Hall sensors (ABI, HALL, magnetic precision encoders);

- SWD port to get direct access to the Chipset. Diagnostics, debugging, and real time data;

- COMM port for various kinds of other communication methods like I2C, ADC, Uart,you can use your Arduino or Raspberry Pi to control the SuperESC!

- USB port for programming.

Features:

Max ERPM(RPM) (separate limits for each direction)

-

With CNC aluminum alloy heat dissipation case, optional water cooling system and forced air cooling system.

-

With larger heat sink case that has better heat dissipation performance.

-

Its heat sink case bottom is coverd by fins that can better heat dissipation.

-

Its PCB board has 4pcs MOS paralleled, could withstand higher current, original version only has 3pcs MOS.

-

Its PCB board with cooper stripe, can reduce resistance in high current, better heat dissipation.

-

With larger capacitor, 9pcs 100V 470μf capacitor, while original version only has 6pcs 80V 470μf.

-

With separate design of strong and weak current circuit board, and between 2 boards added heat sink for better heat dissipation.

-

Exclusive 5V and 12V external power supply interfaces will not cause interference when powering analog circuits such as twist/thumb throttles.

2.Must do a good job of heat dissipation! If place it in a sealed container(recommend touse metal container), it must be forced to be cooled with water. Also make sure your container has enough space for the controller, make sure the cooling tube do not bent, otherwise will influence water flow in cooling tube, also make sure water flow is enough for cooling before office use.

3. Before the new ESC is officially used, please test it with a low-voltage and low-throttle, after success, then slowly increase voltage and throttle. Be sure to pay attention to safety during this period!

4. Recommend to add an electronic switch with short circuit protection function between the ESC and battery, such as MTS2009AS 300A electronic switch or BMS with switch function. It is not recommended to use only contactor without short circuit protection!

5. The battery and motor side terminals must be connected tightly, they can’t be loose. Also please make sure terminals not touch case or other wires, here's the video shows you the way to install cold-pressed terminal connector: https://youtu.be/unFfV9RPPCc

6. In actual use, please use hot melt glue to fix the hall/UART interface cables the corresponding sockets of the ESC, to prevent the cables loose due to the bumps of the vehicle!

7. Please do not disconnect relay switch or electronic switch during usage ! Otherwise it will cause electromagnetic interference, which might damage the controller.

PPM Mapping: Pulselength Start: 1.1ms; Pulselength End: 1.9ms; Pulselength Center: 1.5ms

Recommend Products: Click below pictures to check more information

Share